Testing the winch involved lifting disc weights with a specified steel cable over a height of 2 metres. The winch was successfully able to lift the target weight of 250 kilograms

Second year group design project at University.

Designed, manufactured and tested a highly-loaded rotating machine. Integrated and developed various engineering skills, such as knowledge and understanding of dynamics, materials, design, CAD, manufacture, as well as teamwork and project management.

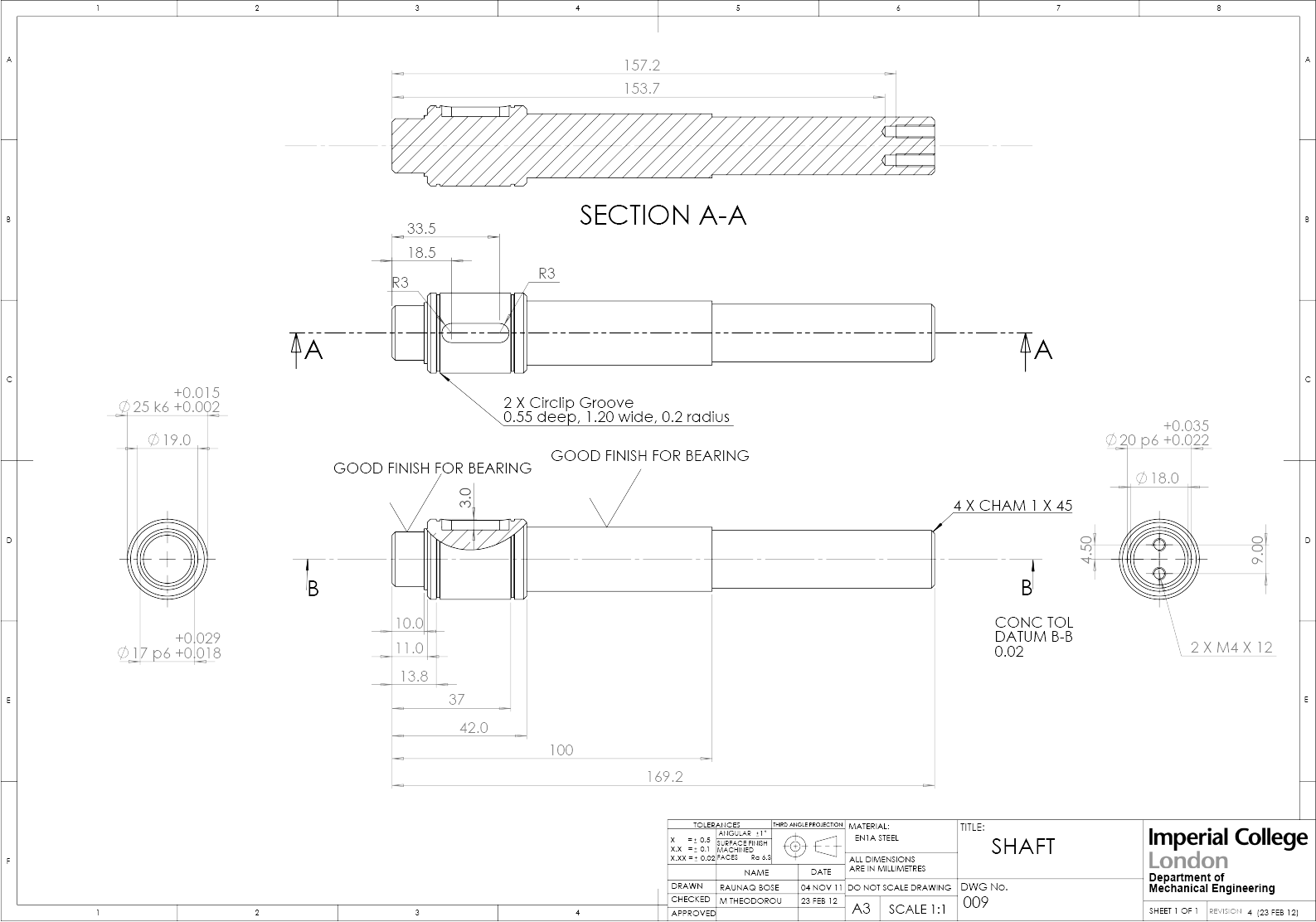

After the team collectively decided on a certain design using a ‘worm and wormwheel,’ and completed all the required calculations for shaft thickness and torque transfer, my main responsibilities were to machine the most complicated part, the main shaft, and to conduct the testing. My other responsibilities included writing part of the report, as well as collating and editing the whole report and designing the poster – for which I was given very positive feedback from my team and the tutors.

Engineering drawing of the primary shaft

One of the reasons the shaft seemed complicated to manufacture was that we were planning to fit the bearings with interference fits. Thus, it was very important that I machined the part within the very small tolerance and with a certain surface finish, which seemed quite tricky with the accuracy of the machines available to us in the workshop.

Poster design